The magnet optimum skewing angle formula is :

P= nr of magnets

Z= nr. of slots.

Example for my motor 60 slot 10 pole: Δ α = (360/20)-(360/60)= 18-6 = 6 degre skewing is ideal for zero cogging torque.

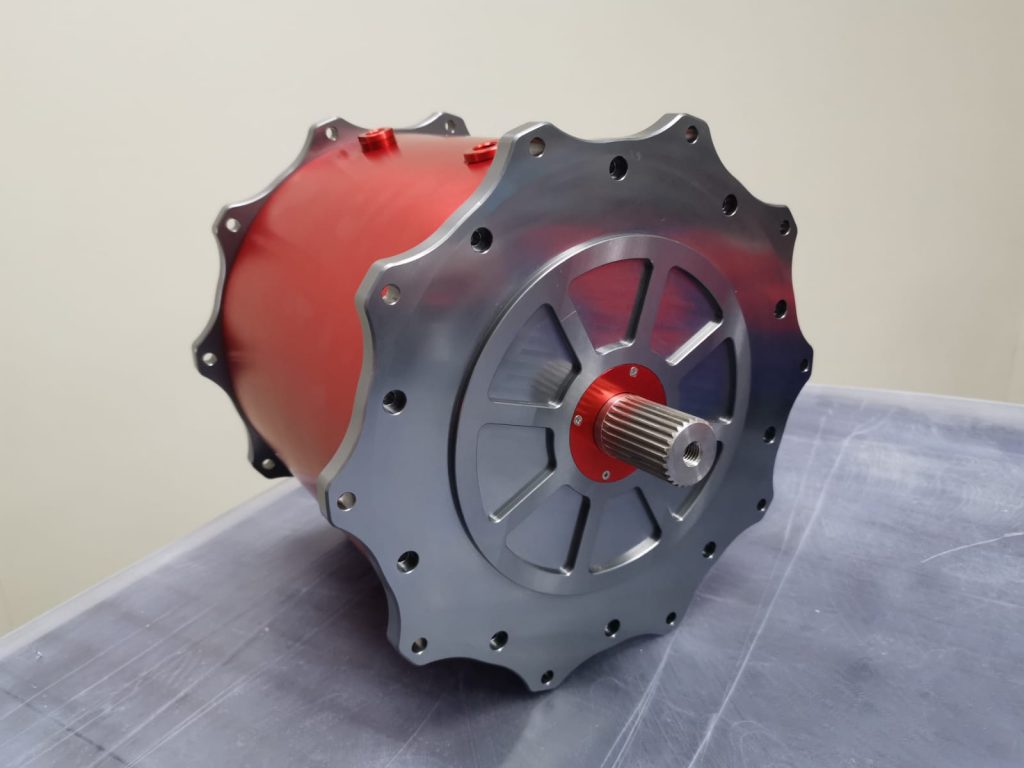

I use 0.2mm thick lamination to achieve highest efficiency on the market, above 97,3%.

Where can we pre-order? I’m very interested!

good artticle, i like it.

thank you

Super Very Good Motor !

Is the design available for sale?

How can i purchase IT?

Is the design available for sale?

I’d like to purchase a motor, please contact me.

Would be very interested in one of these

Hello good afternoon.

Is there an AFPM engine project in sight, either by the company or just to show the differences, I see projects like YASA with absurd torque, I would like to see your knowledge applied in a project like this (ex 250 kW AFPM)

Another subject, What do you think of Yokeless engines? what is your opinion about it?

Hi, I am building a VTOL and would like approximate weight info on your 35KW continuous, BLDC motor. How much are they?.

i like thae article

it can help me

http://www.arrows-hobby.net

Hey! What simulation software do You using. Still Femm or something else?

Which controller did you use that has VESC software and this much power?

Awesome project btw!

Sir we need control of 350KW motor my whatsapp number 8320790363 che to mara whatsapp number please contact me

we are developing a diesel-elctric tracion for a special vehicle, made as a serial hibrid system. The prime mover is a 400 HP diesel engine, we will connect it with two generators (or just one, double power) the same type of the wheels motors (one each side). The system’s connections are the following: the generator, connected to its motor controller, connected with the other motor controlers that will feed DC to the motors controllers of the wheels motors. Two battery packages will be used as buffer and to recover energy.

The power are the following: 400 HP for the generator and 200 HP for each wheel’s motor.

Could you supply the a.m material, i.e #4 motors and #4 motor controllers for our project?

Hi Claudio, Please send me an e-mail foumd at about section.

Regards,

Iulian

Hello, I am a student how make a racing motorcycle, I have make me.motor (64kg for 300kW) never tested it.. I need to make a simple Inverter, I am not looking for extremely high efficiency I just want to put 300kW into my motor. Do you have something you can share? Some picture or schematic?

I know Vesc and want to implement it with a IGBT modul ( FF1000R15, 1700V 500A) me power supply is 400-1000V at up to 400A.

Thanks for your response.

Hi Vladimir, the controllers are available and they are for sale.